A flexible fault classification for gas turbine diagnosis.

1 Introduction

In modern gas turbine health monitoring systems, diagnostic algorithms based on gas path analysis may be considered as principal. They analyze gas path measured variables and are capable of identifying different faults and degradation mechanisms of gas turbine components (e.g. compressor, turbine, and combustor) as well as malfunctions of the measurement system itself (sensor errors).

The fault identification algorithms widely use the pattern recognition theory and, in the last three decades, the use of many recognition techniques has been reported: first of all, Artificial Neural Networks [1], and also Bayesian Approach [2], Support Vector Machines [3], and nonparametric methods [4]. The necessary fault classification is mainly constructed by using a gas path mathematical model. It relates gas path monitored variables with special fault parameters that shift a little the performance maps of engine components (compressors, turbines, burner and others). The maps of each component can be shifted in different directions therefore the model is capable to simulate all possible engine faults and degradation mechanisms.

Fault classes of two types are generally created using the model. A class of single faults of varying severity is formed by changing one fault parameter while a class of multiple faults is formed by independent varying of two or more fault parameters. The classification structure (faulted engine, type of classes, and their number) depends on many factors. Even for the same engine, the classification can vary a lot. Investigating diagnostic algorithms, it is difficult to predict what classification variation will be finally used in a real monitoring system. For this reason, some more probable classification variations are usually analyzed.

In our previous studies [2, 4, 5], only two rigid variations were considered: a classification with only single fault classes and a classification with only multiple fault classes formed by two fault parameters.

The purpose of the present work is to investigate how the classification influences gas turbine diagnostic accuracy. To this end, a flexible fault classification is proposed. The procedure that realizes this classification allows easy creating any new classification variation that can be more complex and more realistic then the classifications previously analyzed. Twelve variations have been prepared for examining in this paper.

The procedure also permits simple choosing the variation to be currently examined. For this fault classification, many fault patterns are generated and diagnosed by one of three neural networks: Multi-Layer Perceptron (MLP), Radial Basis Network (RBN) and Probabilistic Neural Network (PNN). For each network, a probability of correct diagnosis is finally determined to be criteria of diagnostic accuracy. Using these criteria and execution time as an additional criterion, the networks are compared within each classification variation. Such an analysis allows better choosing the best diagnostic technique. An average probability provided by the three networks allows comparison of classification variation. An optimal classification structure can be found as a tradeoff between this probability and the width of coverage of possible component faults.

The paper also introduces and studies a new boundary for fault severity. With this boundary, the fault class description becomes more realistic thus providing more accurate diagnosis.

1. Gas turbine models

Nonlinear thermodynamic model

This

thermodynamic model computes a (m1)-vector

![]() of gas path monitored variables as a function of a vector

of gas path monitored variables as a function of a vector

![]() of steady state operational conditions (control variables and

ambient conditions) as well as a (r1)-vector

of steady state operational conditions (control variables and

ambient conditions) as well as a (r1)-vector

![]() of fault parameters, which can also be named health parameters or

correction factors depending on addressing problems. Given the above

explanation, the thermodynamic model has the following structure:

of fault parameters, which can also be named health parameters or

correction factors depending on addressing problems. Given the above

explanation, the thermodynamic model has the following structure:

![]()

There

are various types of gas turbine deterioration and faults such as

fouling, tip rubs, seal wear, erosion, and foreign object damage.

Since such real defects occur rarely during maintenance, the

thermodynamic model is a unique technique to create necessary class

descriptions. To take into account the component performance changes

induced by real gradual deterioration mechanisms and abrupt faults,

the fault parameters

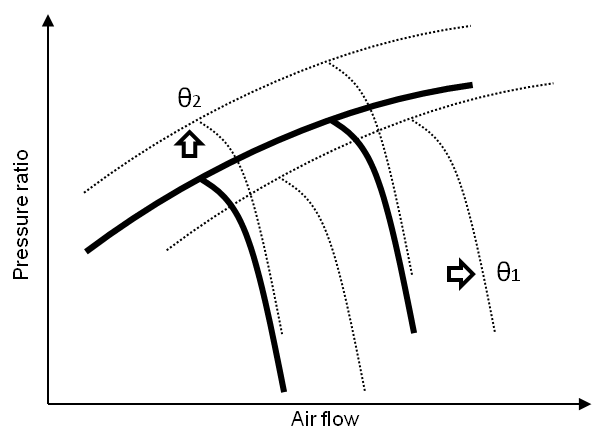

![]() that shift a little the components’ maps as shown in Fig.1.

that shift a little the components’ maps as shown in Fig.1.

Mathematically, the model is a system of nonlinear algebraic equations reflecting mass, heat, and energy balance for all components operating under stationary conditions.

Fig. 1. Compressor map shifting by the fault parameters

The thermodynamic model for steady states has wide applications in gas turbine diagnostics. First, as shown before and in more detail in [5], this model is used to describe particular faults or complete fault classification. Second, the thermodynamic model is an integral part of numerous diagnostic algorithms based on system identification such as described in [6]. Third, this nonlinear model allows computing simpler models, like a linear model used in [7] and in the present paper to create flexible fault classifications.

Linear static model

The

linear static model presents linearization of nonlinear dependency

![]() between gas path variables and fault parameters determined for a

fixed operating condition

between gas path variables and fault parameters determined for a

fixed operating condition

![]() .

The model is given by a vectorial expression:

.

The model is given by a vectorial expression:

![]()

It

connects a vector

![]() of small relative changes of the fault parameters with a vector

of small relative changes of the fault parameters with a vector

![]() of

the corresponding relative deviations of the monitored variables by

a matrix

of

the corresponding relative deviations of the monitored variables by

a matrix

![]() of influence coefficients (influence matrix).

of influence coefficients (influence matrix).

Since linearization errors are not too great, about some per cent, the linear model can be successfully applied for fault simulation at any fixed operating point. However, when it is used for estimating fault parameters by system identification methods like in study [6,8], estimation errors can be significant. Given the simplicity of the linear model and its utility for analytical analysis of complex diagnostic issues, this model will remain important in gas turbine diagnostics.

2. Methodology for gas turbine diagnosis

2.1 Deviations

By

direct analysis of the variables themselves it is difficult to

discriminate performance degradation effects from great changes due

to different operating modes. To draw useful diagnostic information

from raw recorded data, a total gas turbine diagnostic process

usually includes a preliminary procedure of computing deviations.

The deviations are defined as differences between measured and

engine baseline values. As the baseline depends on an engine

operating condition, it can be written as function

![]() (

(![]() usually called a baseline function. With this model the deviations

for each monitored variables

usually called a baseline function. With this model the deviations

for each monitored variables

![]() is computed in a relative form:

is computed in a relative form:

where

![]() denotes a measured value.

denotes a measured value.

2.2 Diagnostic space

As mentioned before, models are used in gas turbine diagnostics to describe engine performance degradation and faults and the deviations are employed to reveal the degradation influence. These deviations are written in relative form and normalized so as to facilitate simulating faults and their subsequent recognition. At a steady state, the deviation is defined for i-th measured variable as:

where

![]() is the amplitude of possible random fluctuations in the original

deviation

is the amplitude of possible random fluctuations in the original

deviation

![]() .

To take into account possible measurement errors, the vector

.

To take into account possible measurement errors, the vector

![]() of random variables distributed within the interval (-1,1) is added.

A resultant vector

of random variables distributed within the interval (-1,1) is added.

A resultant vector

![]()

corresponds to the deviations that are calculated in practice for actual measurements.

2.3 Principles for developing classification

Engine

faults vary considerably. Hence, for the purposes of engine

diagnostics this variety has to be broken down into a limited number

of classes. In the pattern recognition theory, it is often supposed

that an object state

![]() can belong only to one of

can belong only to one of

![]() present classes

present classes

![]()

Consequently

![]()

We accept this hypothesis for a gas turbine fault classification.

Fault classifications can contain two different types of fault classes: singular or multiple classes. The first type works with only one fault parameter while the second one is formed by independent changes of two or more fault parameters in order to represent more complex faults in gas turbines.

For

each class, singular or multiple, numerous patterns

![]() are generated according to expression (4) setting the necessary

quantities

are generated according to expression (4) setting the necessary

quantities

![]() and

and

![]() by the uniform and Gaussian distributions accordingly. A typical

number of patterns per class is 1000. A totality

by the uniform and Gaussian distributions accordingly. A typical

number of patterns per class is 1000. A totality

![]() of all classification’s patterns is employed to train the used

neural network and is therefore called a learning set.

of all classification’s patterns is employed to train the used

neural network and is therefore called a learning set.

2.4 Recognition decision making

A

nomenclature of possible diagnosis

![]() made by a recognition technique (neural network within the present

paper) corresponds to the accepted classification (6). To make a

diagnosis

made by a recognition technique (neural network within the present

paper) corresponds to the accepted classification (6). To make a

diagnosis

![]() a criterion

a criterion

![]() specific

for each technique is introduced as a measure of membership of a

current pattern

specific

for each technique is introduced as a measure of membership of a

current pattern

![]() in class

in class

![]() .

To determine the functions

.

To determine the functions

![]() ,

a learning set

,

a learning set

![]() is used. After calculating all values

is used. After calculating all values

![]() ,

a decision rule

,

a decision rule

![]()

is applied.

2.5 Recognition accuracy

To

verify a recognition technique determined with the help of the

learning set, one more set is required. The necessary set

![]() ,

called a validation set, is created in the same way as the set

,

called a validation set, is created in the same way as the set

![]() .

The only difference is that other series of random numbers is

generated to simulate fault severity and errors in the deviations.

.

The only difference is that other series of random numbers is

generated to simulate fault severity and errors in the deviations.

Every

pattern in the validation set belongs to a known class. Comparing

this class

![]() with the diagnosis

with the diagnosis

![]() ,

we can compute probabilities

,

we can compute probabilities

![]() and compose a confusion matrix (Table 1). Its diagonal elements

and compose a confusion matrix (Table 1). Its diagonal elements

![]() form a vector

form a vector

![]() of true diagnosis probabilities that are indices of classes’

distinguishability. Mean number of these elements – scalar

of true diagnosis probabilities that are indices of classes’

distinguishability. Mean number of these elements – scalar

![]() –

characterizes total engine diagnosability. No diagonal elements are

wrong diagnosis probabilities. They help to identify the causes of

bad class distinguishability. For 1000 patterns per class, the

computational precision of the mean probability

–

characterizes total engine diagnosability. No diagonal elements are

wrong diagnosis probabilities. They help to identify the causes of

bad class distinguishability. For 1000 patterns per class, the

computational precision of the mean probability

![]() is approximately ±0.01. In order to enhance the precision, each

calculation of

is approximately ±0.01. In order to enhance the precision, each

calculation of

![]() is repeated in the present study 100 times, each time with new

series of random numbers. The 100 corresponding random values of

is repeated in the present study 100 times, each time with new

series of random numbers. The 100 corresponding random values of

![]() are averaged, resulting in a probability Pav

with higher precision of ±0.001.

are averaged, resulting in a probability Pav

with higher precision of ±0.001.

Table 1

Confusion matrix

|

Diagnosis |

Classes |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

… |

… |

… |

|

… |

|

|

|

|

|

|

3. Pattern recognition techniques

Three different artificial neural networks described below have been chosen in the present study for gas turbine fault recognition.

3.1 Multi-Layer Perceptron (MLP)

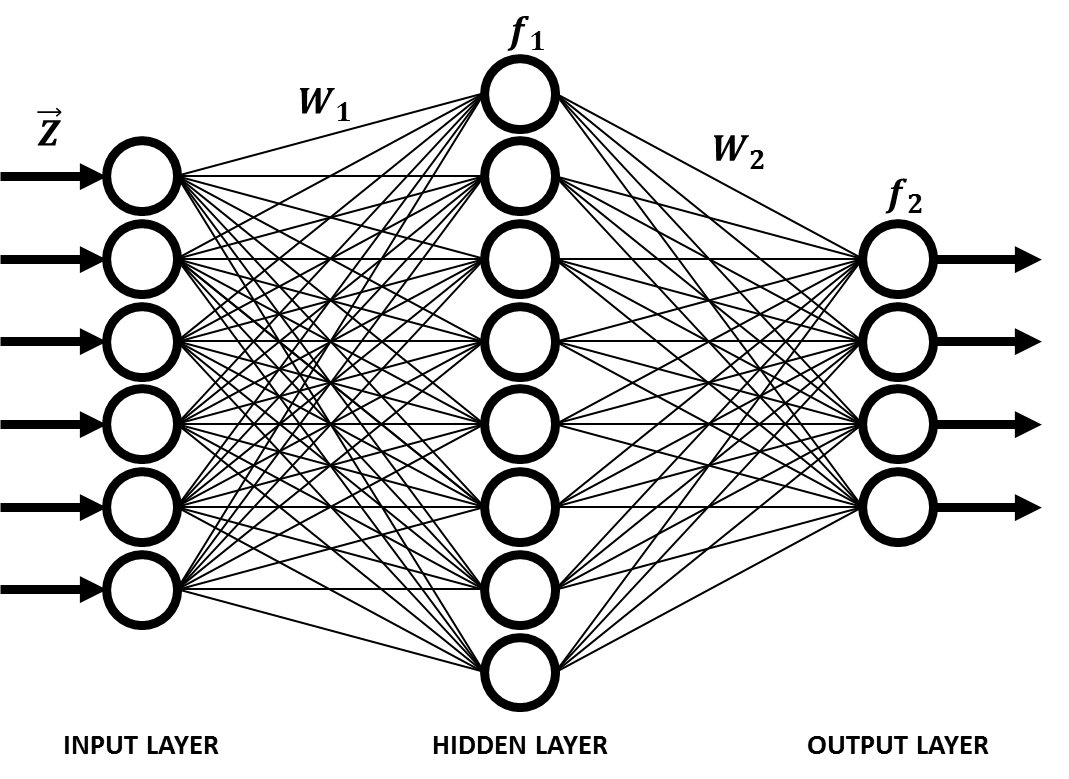

The

MLP is a feedforward artificial neural network model that maps sets

of input data onto a set of appropriate outputs. It consists of

multiple layers of nodes in a directed graph, with each layer fully

connected to the next one. Except for the input nodes, each node is

a neuron with a nonlinear activation function (Fig. 2). When the

perceptron is applied to a classification problem, each output k

gives a closeness measure between the analyzed input pattern

![]() and a class

and a class

![]() .

.

Fig. 2. Typical MLP structure

During the learning, unknown weight coefficients and biases are determined by a back-propagation algorithm, in which a network output error is propagated backwards to correct these unknown quantities. They are corrected in the direction that reduces the error unless a global error minimum is reached. The back-propagation algorithm needs differentiable transfer functions and they usually are of a sigmoid or linear type. MLP is a modification of the standard linear perceptron and can distinguish data that are not linearly separable

3.2 Radial Basis Network (RBN)

A

RBN is an artificial neural network that uses radial basis functions

as activation functions. The output of the network is a linear

combination of radial basis functions of the inputs and neuron

parameters. A radial basis neuron operates as follows. Neuron's

weight coefficients form a weight vector that is one of learning

patterns. First, a distance between the weight vector and an input

vector

![]() is computed. This distance is then divided by a bias b

resulting in an input n

to a radial basis transfer function (RBF). The RBF finally computes

a neuron’s output according to an expression

is computed. This distance is then divided by a bias b

resulting in an input n

to a radial basis transfer function (RBF). The RBF finally computes

a neuron’s output according to an expression

![]() .

When the distance is 0, this function has a maximum value

.

When the distance is 0, this function has a maximum value

![]() .

The function decreases when the distance increases. The bias b

allows changing an action area (window) of the neuron and is called

spread. The output layer of the RBN works similarly to a usual

perceptron output layer with a linear transfer function.

.

The function decreases when the distance increases. The bias b

allows changing an action area (window) of the neuron and is called

spread. The output layer of the RBN works similarly to a usual

perceptron output layer with a linear transfer function.

3.3 Probabilistic Neural Network

A

probabilistic network, specific type of radial basis networks, is

specially intended for classification problems. It consists of three

layers. The hidden layer is formed and operates just like the same

layer of the RBN algorithm. It is built from learning patterns

united in a matrix

![]() .

Each learning pattern

.

Each learning pattern

![]() specifies a center of the RBN of one hidden neuron. A Euclidean

distance

specifies a center of the RBN of one hidden neuron. A Euclidean

distance

![]() between the function center

between the function center

![]() and the input pattern

and the input pattern

![]() is firstly computed. The distance

is firstly computed. The distance

![]() divided by the spread b

is a hidden neuron input. A radial basis function

divided by the spread b

is a hidden neuron input. A radial basis function

![]() then calculates a neuron output

then calculates a neuron output

![]() .

The closer the input vector is situated to the neuron center, the

greater the neuron output will be. Thus, elements of a vector

.

The closer the input vector is situated to the neuron center, the

greater the neuron output will be. Thus, elements of a vector

![]() indicate how close the input pattern is to the learning patterns.

indicate how close the input pattern is to the learning patterns.

The

output or classification layer differs from the RBN output layer.

Each classification neuron corresponds to one of the analyzed

classes. An input of the classification neuron, which is interpreted

as a probability of this class, is computed as a sum of the signals

![]() related with the learning patterns of the same class. In other

words, each hidden neuron is connected with only one classification

neuron and connection weights are equal to one. To realize such a

connection, a matrix

related with the learning patterns of the same class. In other

words, each hidden neuron is connected with only one classification

neuron and connection weights are equal to one. To realize such a

connection, a matrix

![]() is composed in a particular way from zero and one elements and a

product

is composed in a particular way from zero and one elements and a

product

![]() is computed. It is an input vector for the classification layer and

consists of probabilities of all considered classes. Finally, the

classification layer transfer function

is computed. It is an input vector for the classification layer and

consists of probabilities of all considered classes. Finally, the

classification layer transfer function

![]() produces a 1 corresponding to the largest probability, and 0's for

the other network outputs. Thus, the PNN classifies the input vector

produces a 1 corresponding to the largest probability, and 0's for

the other network outputs. Thus, the PNN classifies the input vector

![]() into a specific class on the basis of a probability measure.

into a specific class on the basis of a probability measure.

4. Calculation conditions

The approach and three neural networks described above were applied for diagnosing a turboshaft stationary power plant with a free turbine intended for driving a centrifugal compressor in natural gas pipelines. Five components of the engine are diagnosed: inlet device, axial compressor, combustion chamber, compressor turbine and power turbine. An engine operating point is given by a constant compressor rotational speed 10700 rpm and standard atmospheric conditions. The six gas path variables of Table 2 corresponding to an engine standard measurement system are available for monitoring. To simulate gas path and measurement system faults, the eighteen fault parameters from Table 3 are involved.

Table 2

Monitored variables

|

Number |

Variable* |

Symbol |

|

1 |

Compressor pressure |

Pc |

|

2 |

Turbine pressure |

Pt |

|

3 |

Compressor temperature |

Tc |

|

4 |

Turbine temperature |

Tt |

|

5 |

Power turbine temperature |

Tpt |

|

6 |

Fuel flow |

Gf |

* component pressures and temperatures correspond to a component discharge section

Table 3

Fault parameters

|

Number |

Fault parameter |

Symbol |

|

1 |

Compressor air flow |

δGc |

|

2 |

Compressor efficiency |

δηc |

|

3 |

Turbine gas flow |

δGt |

|

4 |

Turbine efficiency |

δηt |

|

5 |

Power turbine gas flow |

δGpt |

|

6 |

Power turbine efficiency |

δηpt |

|

7 |

Combustion chamber pressure recovery factor |

δσcc |

|

8 |

Combustion efficiency |

δηcc |

|

9 |

Inlet pressure loses factor |

δσin |

|

10 |

Compressor pressure |

δPc |

|

11 |

Turbine pressure |

δPt |

|

12 |

Compressor temperature |

δTc |

|

13 |

Turbine temperature |

δTt |

|

14 |

Power turbine temperature |

δTpt |

|

15 |

Fuel flow |

δGf |

|

16 |

Inlet pressure |

δPin |

|

17 |

Inlet temperature |

δTin |

|

18 |

High pressure turbine speed |

δnhp |

On the basis of the fault parameters specified in Table 3, the next section introduces various fault classification variations.

5. Fault classification variations

With the intention of studying the influence of the fault classification structure on final diagnostic accuracy, twelve fault variations are introduced. These variations contain different class quantities, fault parameters, fault development directions (positive or negative) and engine components. These variations are specified in Table 4 and additionally briefly described below.

Variation 1: It has nine singular classes formed by gas path parameters whose changes are negative.

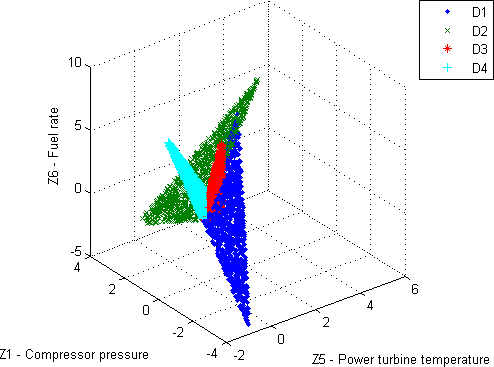

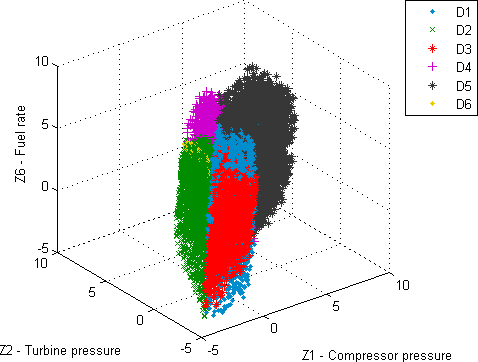

Variation 2: It is formed by four multiple classes with two gas path parameters per class and grouped by an engine component: compressor, turbine, power turbine and combustion chamber (Fig. 3).

Variation 3: The combination of variation 1 and three singular classes with positive direction of a fault parameter (turbine and power turbine air flow parameters and combustion chamber pressure ratio) to simulate burns in hot parts.

Variation 4: The combination of variation 2 + three multiple classes formed by turbine and power turbine air flow parameters, combustion chamber pressure ratio and their respective efficiencies (negative direction).

Variation 5: It contains six singular classes of sensor faults in

.

Each of them has positive and negative directions of fault.

.

Each of them has positive and negative directions of fault.

Variation 6: The combination of variations 3 and 5 resulting in eighteen singular classes to simulate gas path faults and sensor errors.

Variation 7: Formed by seven multiple classes of variation 4 and six singular classes (sensor faults) with double limits.

Variation 8: It has the six sensor faults in

and three singular classes of sensor faults in

and three singular classes of sensor faults in

.

.

Variation 9: Formed by three multiple classes (turbine and power turbine air flow parameters, combustion chamber pressure ratio and their respective efficiencies) and one multiple class of faults in compressor.

Variation 10: It contains nine singular classes: three singular classes with double direction of fault (turbine and power turbine air flow parameters and combustion chamber pressure ratio), four efficiencies for all components, one for the compressor air flow and another one for the inlet pressure loses factor.

Variation 11: In this variation, each class is created by four fault parameters. It is formed by the combination of air flow parameters (with the exception of the combustion chamber pressure ratio) and efficiencies. The first three classes are formed by combining the turbine, the power turbine and the combustion chamber with the compressor, the fourth and the fifth - by combining the power turbine and the combustion chamber with the turbine. The last class is formed as the combination of the power turbine and the combustion chamber (Fig. 4).

Variation 12: It is practically the same as variation 11, but, in this case all the classes have negative directions to simulate gas path faults.

For each classification variation, fault diagnosis was performed by with three neural networks: Multi-Layer Perceptron, Radial Basis Network and Probabilistic Neural Network and the probability Pav and execution time were determined for each network. Table 5 shows all the results. All the computation was performed in a Dell Inspiron One Desktop: Intel Pentium G2020T processor, 2.5 GHz, and 4 GB of RAM.

Fig. 3. Classification variation 2: four multiple classes with two fault parameters

Analyzing the probabilities, one can state that the differences between the networks within the same classification variation are not great (excepting variation 6),

about 0.015 (1.5%), while the difference between the variations can reach the value 0.10. Thus, these results reaffirm once more the conclusion drawn in [9] that many recognition techniques may yield the same gas turbine diagnosis accuracy.

Fig. 4. Classification variation 11: six multiple classes with four fault parameters

The

execution time includes 100 cycles of calculation of the mean

probability

![]() .

Each cycle consists of a learning stage with thousands diagnosis

cycles of a validation stage at which the probability

.

Each cycle consists of a learning stage with thousands diagnosis

cycles of a validation stage at which the probability

![]() is computed. In Table 5, we can see that this total time is by far

smaller for the PNN for all classifications. This is explained by

the fact that this network does not need a learning stage. Thus, the

PNN seems to be the simplest network to tailor for gas turbine

diagnosis.

is computed. In Table 5, we can see that this total time is by far

smaller for the PNN for all classifications. This is explained by

the fact that this network does not need a learning stage. Thus, the

PNN seems to be the simplest network to tailor for gas turbine

diagnosis.

Table 4

Variations of classification and their fault class formation

|

VARIATION |

FAULT CLASSES |

|||||||||||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

|

|

Variation 1 |

-δGc |

-δηc |

-δGt |

-δηt |

-δGpt |

-δηpt |

-δσcc |

-δηcc |

-δσin |

|

|

|

||||||

|

Variation 2 |

-δGc -δηc |

-δGt -δηt |

-δGpt -δηpt |

-δσcc -δηcc |

|

|

|

|

|

|

|

|

|

|||||

|

Variation 3 |

-δGc |

-δηc |

-δGt |

-δηt |

-δGpt |

-δηpt |

-δσcc |

-δηcc |

-δσin |

+δGt |

+δGpt |

+δσcc |

|

|||||

|

Variation 4 |

-δGc -δηc |

-δGt -δηt |

-δGpt -δηpt |

-δσcc -δηcc |

+δGt -δηt |

+δGpt -δηpt |

+δσcc -δηcc |

|

||||||||||

|

Variation 5 |

±δPc |

±δPt |

±δTc |

±δTt |

±δTpt |

±δGf |

|

|||||||||||

|

Variation 6 |

-δGc |

-δηc |

-δGt |

-δηt |

-δGpt |

-δηpt |

-δσcc |

-δηcc |

-δσin |

+δGt |

+δGpt |

+δσcc |

±δPc |

±δPt |

±δTc |

±δTt |

±δTpt |

±δGf |

|

Variation 7 |

-δGc -δηc |

-δGt -δηt |

-δGpt -δηpt |

-δσcc -δηcc |

+δGt -δηt |

+δGpt -δηpt |

+δσcc -δηcc |

±δPc |

±δPt |

±δTc |

±δTt |

±δTpt |

±δGf |

|

||||

|

Variation 8 |

±δPc |

±δPt |

±δTc |

±δTt |

±δTpt |

±δGf |

±δPin |

±δTin |

±δnhp |

|

||||||||

|

Variation 9 |

-δGc -δηc |

±δGt -δηt |

±δGpt -δηpt |

±δσcc -δηcc |

|

|||||||||||||

|

Variation 10 |

-δGc |

-δηc |

-δηt |

-δηpt |

-δηcc |

-δσin |

±δGt |

±δGpt |

±δσcc |

|

||||||||

|

Variation 11 |

-δGc -δηc ±δGt -δηt |

-δGc -δηc ±δGpt -δηpt |

-δGc -δηc ±δσcc -δηcc |

±δGt -δηt ±δGpt -δηpt |

±δGt -δηt ±δσcc -δηcc |

±δGpt -δηpt ±δσcc -δηcc |

|

|||||||||||

|

Variation 12 |

-δGc -δηc -δGt -δηt |

-δGc -δηc -δGpt -δηpt |

-δGc -δηc -δσcc -δηcc |

-δGt -δηt -δGpt -δηpt |

-δGt -δηt -δσcc -δηcc |

-δGpt -δηpt -δσcc -δηcc |

|

|||||||||||

6. Boundaries for multiple fault classes

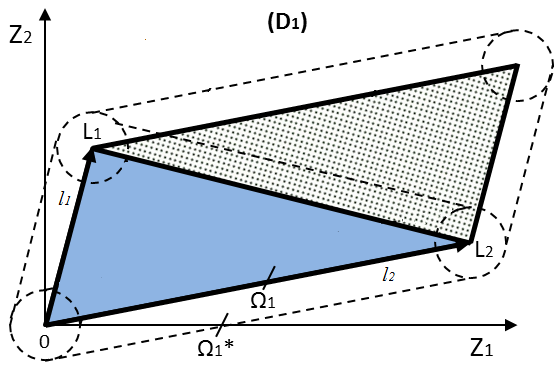

When

multiple faults are simulated by summing the influence of each fault

parameter, there is the risk that the simulated fault exceeds a

severity limit of real faults. In Fig.3, a multiple class D1

created by two fault parameters is illustrated. The point “0”

corresponds here to an engine normal state. Each of the vectors OL1

and OL2

results

from the change of one fault parameter. Points L1

and

L2

and

vector lengths l1

and l2

correspond to an engine health limit. An area

![]() of deviation vectors

of deviation vectors

![]() without errors presents a parallelogram and area

without errors presents a parallelogram and area

![]() corresponds to deviation vectors

corresponds to deviation vectors

![]() with errors. It can be seen that vectors

with errors. It can be seen that vectors

![]() in the upper right corner of the parallelogram can be longer than

base vectors OL1

and OL2

produced by a maximal change of the corresponding fault parameters.

In other words, simulated faults can have higher severity than real

ones.

in the upper right corner of the parallelogram can be longer than

base vectors OL1

and OL2

produced by a maximal change of the corresponding fault parameters.

In other words, simulated faults can have higher severity than real

ones.

Fig. 5. Straight line boundary

To make the simulated faults more realistic, we previously used a linear boundary L1L2 that restricts fault pattern vectors inside the triangle OL1L2. However, this boundary becomes too restrictive when the angle L1OL2 increases.

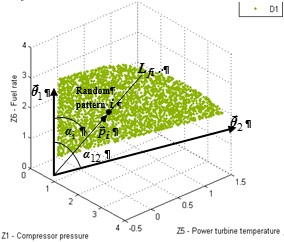

An ideal boundary seems to us like a smooth curve formed by a vector that turns from OL1 to OL2 and gradually changes its length from l1 to l2 proportionally to the turning angle. It is proposed to express this length by:

![]()

where

![]() is the angle between a current vector and the first base vector and

is the angle between a current vector and the first base vector and

![]() is the angle between the two base vectors. As can be seen, the

boundary determined by (9) corresponds to the Archimedean spiral.

Figure 6 illustrates action of the proposed boundary: the deviation

vectors

is the angle between the two base vectors. As can be seen, the

boundary determined by (9) corresponds to the Archimedean spiral.

Figure 6 illustrates action of the proposed boundary: the deviation

vectors

![]() that are inside the curve are only accepted.

that are inside the curve are only accepted.

Fig. 6. Archimedeaspiral boundary

(Two fault parameters)

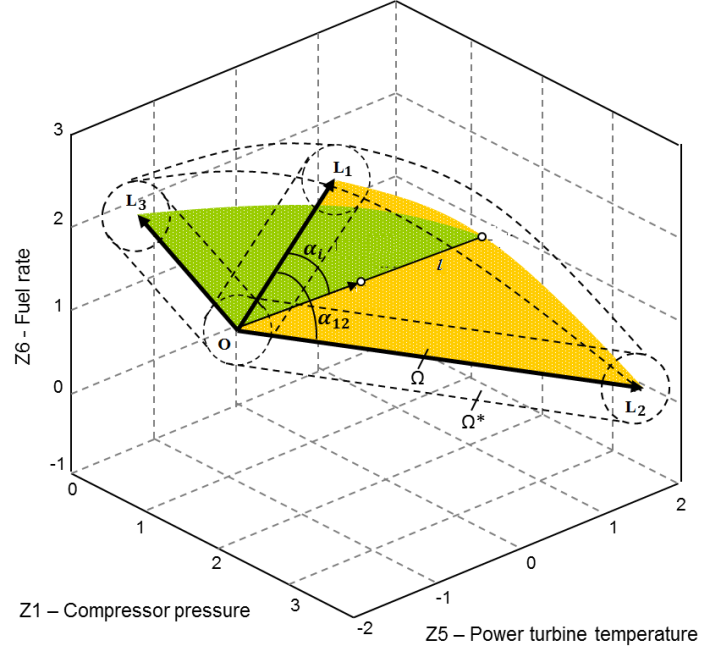

The described boundary rule can be easily extended on the case of three fault parameters illustrated by Fig.7. The boundary vector of the length l determined in the plane of the first and second fault parameters (orange area) is considered as a base vector. The second base vector OL3 is produced by the third fault parameters. The boundary is determined in the plane of these two base vectors (green area). For the case of four and more fault parameters, we only need to repeat the above procedure.

To

better understand the importance of the new boundary, three boundary

options have been examined: no boundary (parallelogram area

![]() ),

straight line (triangle

area

),

straight line (triangle

area

![]() ),

and

Archimedean

spiral. The boundaries were applied for multiple faults of

classification variations 2 and 12. For each option and each

variation, the three selected neural networks were used by turn for

computing average true diagnosis probabilities Pav.

Table 6 contains all the results, which help to draw the following

conclusions. First, the new boundary results in a visible change of

the probability Pav

(up to 0.04). This change can be greater for particular fault

classes. Second, for all cases the “Archimedean spiral”

probability occupies an intermediate position between “No

boundary” probability and “Straight

line”

probability. This is naturally explained by the fact that the

Archimedean spiral curve is situated between the straight

line and the parallelogram sides. Third,

for the new boundary, the difference between the recognition

techniques (three networks) remains small: 0.0045 for classification

variation 2 and 0.0133 for variation 12.

),

and

Archimedean

spiral. The boundaries were applied for multiple faults of

classification variations 2 and 12. For each option and each

variation, the three selected neural networks were used by turn for

computing average true diagnosis probabilities Pav.

Table 6 contains all the results, which help to draw the following

conclusions. First, the new boundary results in a visible change of

the probability Pav

(up to 0.04). This change can be greater for particular fault

classes. Second, for all cases the “Archimedean spiral”

probability occupies an intermediate position between “No

boundary” probability and “Straight

line”

probability. This is naturally explained by the fact that the

Archimedean spiral curve is situated between the straight

line and the parallelogram sides. Third,

for the new boundary, the difference between the recognition

techniques (three networks) remains small: 0.0045 for classification

variation 2 and 0.0133 for variation 12.

Fig. 7. Archimedean spiral boundary

(Three fault parameters).

Table 5

Average true diagnosis probabilities Pav for different classification variations.

|

Variation |

Probabilities |

|

Time |

||||

|

MLP |

RBN |

PNN |

MLP |

RBN |

PNN |

||

|

1 |

0.8172 |

0.8169 |

0.8099 |

20 min |

4 h 11 min |

27 min |

|

|

2 |

0.8732 |

0.8759 |

0.8720 |

36 min |

57 min |

6 min |

|

|

3 |

0.8091 |

0.8072 |

0.8037 |

59 min |

3 h 48 min |

29 min |

|

|

4 |

0.8490 |

0.8524 |

0.8474 |

5 h 32 min |

2 h 44 min |

23 min |

|

|

5 |

0.8033 |

0.8080 |

0.8036 |

2 h 21 min |

|

14 min |

|

|

6 |

0.6805 |

0.7319 |

0.7316 |

6 h 42 min |

4 h 34 min |

36 min |

|

|

7 |

0.7362 |

0.7616 |

0.7567 |

5 h 28 min |

4 h 41 min |

30 min |

|

|

8 |

0.7828 |

0.7965 |

0.7910 |

1 h 10 min |

3 h 40 min |

27 min |

|

|

9 |

0.9279 |

0.9280 |

0.9260 |

26 min |

1 h 6 min |

6 min |

|

|

10 |

0.7909 |

0.8017 |

0.7930 |

4 h 39 min |

3 h 41 min |

22 min |

|

|

11 |

0.8075 |

0.7867 |

0.7775 |

4 h 44 min |

2 h 21 min |

14 min |

|

|

12 |

0.8209 |

0.8184 |

0.8076 |

6 h 21 min |

2 h 19 min |

17 min |

|

Table 6

Average true diagnosis probabilities Pav for different fault severity boundaries

|

Boundary option |

Probabilities |

||||||

|

Variation 2 |

|

Variation 12 |

|||||

|

MLP |

RBN |

PNN |

MLP |

RBN |

PNN |

||

|

No boundary |

0.9164 |

0.9182 |

0.9140 |

|

0.8288 |

0.8248 |

0.8156 |

|

Straight line |

0.8732 |

0.8759 |

0.8720 |

0.8120 |

0.8105 |

0.8005 |

|

|

Archimedean spiral |

0.9121 |

0.9136 |

0.9091 |

0.8209 |

0.8184 |

0.8076 |

|

Conclusions

In investigations and practice of gas turbine diagnosis, fault classifications vary considerably. That is why, the present paper proposes a flexible fault classification that allows creating any necessary totality of fault classes of different types. Twelve classification variations were introduced and investigated in the paper. For each variation, an average probability of correct fault diagnosis was determined using by turn on of three neural networks as a fault recognition technique. Additionally, a new boundary that restricts fault severity was proposed and examined. The following conclusions have been drawn as a result of the investigations.

- The procedure of flexible classification has proven to create any necessary totality of fault classes of different type y complexity. Formation of a new classification variation and change from one variation to another is simple and does not need reprogramming the software.

- For all classification variation examined, three networks provide practically equal average probability of correct diagnosis. This confirms the conclusion made in previous studies that many recognition techniques can have the same diagnostic accuracy.

- Among the three networks, the probabilistic neural network seems to be simplest gas turbine fault recognition technique.

- The new boundary (Archimedean spiral) proposed for restricting the severity of simulated faults makes the simulation more realistic and allows to determine more precisely the level of diagnostic accuracy.

Acknowledgments

The work has been carried out with the support of the National Polytechnic Institute of Mexico (research project 20144199) and the National Council of Science and Technology (CONACYT).

References

1. Romessis, C. Bayesian Network Approach for Gas Path Fault Diagnosis [Text] / C. Romessis, K. Mathioudakis // ASME Journal of Engineering for Gas Turbines and Power. − 2006. − Vol. 128, Issue 1. − P. 64-72.

2. Loboda, I. Gas Turbine Fault Recognition Trustworthiness [Text] / I. Loboda, S. Yepifanov // Cientifica, Revista del Instituto Politecnico Nacional de Mexico. − 2006. − Vol. 10, Is. 2. − P. 65-74.

3. Butler, S. An Assessment Methodology for Data-Driven and Model Based Techniques for Engine Health Monitoring [Text] / S.W. Butler, K.R. Pattipati, A.J. Volponi // Proc. IGTI/ASME Turbo Expo 2006, Barcelona, Spain, May 8-11, 2006. − 9 p.

4. García Díaz, J. Diagnóstico de Turbinas de Gas con el Criterio de la Densidad de Probabilidad [Text] / J. García Díaz, I. Loboda, J.L. Pérez Ruiz // Proceedings of the VII International Congress of Electromechanical and Systems Engineering, Mexico City, Mexico, Oct 27-31, 2014. -7p.

5. Loboda, I. A Generalized Fault Classification for Gas Turbine Diagnostics on Steady States and Transients [Text] / I. Loboda, S. Yepifanov, Ya. Feldshteyn // Journal of Engineering for Gas Turbines and Power.-2007.- Vol.129, No.4.- P. 977-985.

6. Pinelli, M. Gas Turbine Field Performance Determination: Sources of Uncertainties [Text] / M. Pinelli, P.R. Spina // Journal of Engineering for Gas Turbines and Power.-2002.- Vol.124, No.1.- P. 155-160.

7. Pérez Ruiz, J.L. Clasificación Flexible de Fallas para el Diagnóstico Paramétrico de Turbinas de Gas [Text] / J.L. Pérez Ruiz, I. Loboda, I. González Castillo // Proceedings of the VII International Congress of Electromechanical and Systems Engineering, Mexico City, Mexico, Oct 27-31, 2014. -8p.

8. Kamboukos, Ph. Comparison of Linear and Nonlinear Gas Turbine Performance Diagnostics [Text] / Ph. Kamboukos, K. Mathioudakis // Journal of Engineering for Gas Turbines and Power.-2005.- Vol.127, No.1.- P. 49-56.

9. Loboda, I. Gas turbine fault recognition using probability density estimation [Text] / I. Loboda // Proceedings of the ASME Turbo Expo 2014 International Technical Congress, Dusseldorf, Germany, June 16-20, - 2014. - 13p., ASME Paper No. GT2014-27265.